One of the reasons I chose the MX5 series is because of how basic the cars are in a mechanical sense. I really wanted to learn more about how cars work and how to work on them. I also thought this more intimate knowledge of the car would help me in my racing, as I could diagnose faults quicker or know how to easier adapt to the car.

The Immediate Alterations

After buying the car in 2018, I knew since I was going to be doing the majority of the work myself, it was going to be a long while before I was going to be able to take it racing. This blog post will detail all the work I did myself to the car in the three years before taking it to Thrussington garage for its final adjustments in 2021. The car I bought was standard with the only obvious modifications being to the sound system. Although the previous owner seemed very pleased with his handiwork, unfortunately it was the first thing stripped from the car.

The plan was to immediately start stripping the interior car of anything un-needed in the name of simplification, and more importantly, weight reduction. I removed the roll bar (incoming roll cage!), carpets, speakers (including wiring) and any un-needed trim and almost everything from the centre console. This was a really easy job, and when I discovered that you can pretty much take this car apart with a screwdriver, and an 8mm and 10mm socket.

From here I then took the seats out, and sanded away all the glue that was holding the carpets in place. I then cleaned this area with white spirit before painting it with Hammerite to add a layer of protection, from both rust and also general use.

Piece by Piece

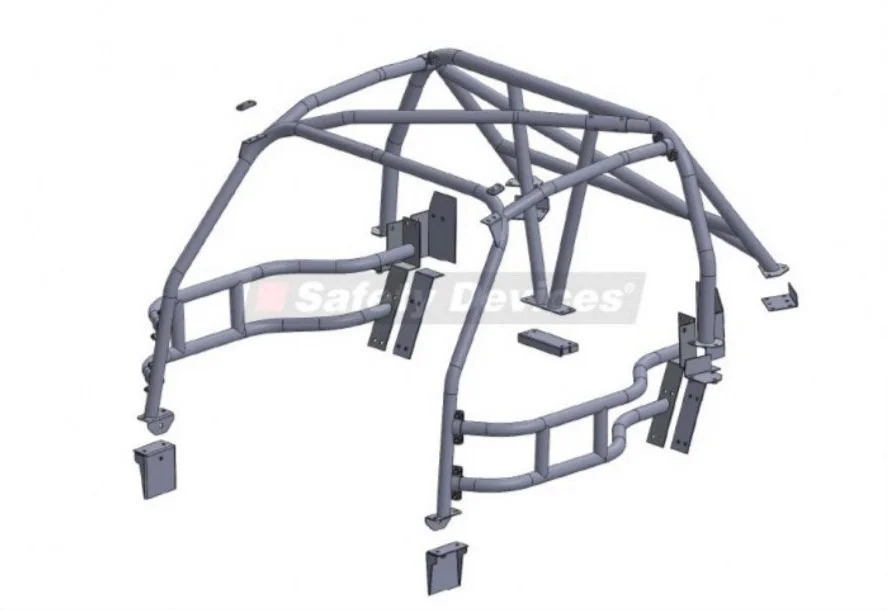

The next big upgrade would come over easter when I got the roll cage. At almost triple the value of the car, it took me a while to be able to order one, however I couldn’t wait to see it in the car. After discussing with Paul Sheard the one I needed for my car and series I put my order in. My Grandad was to fit the roll cage as he has extensive experience welding and fabricating. Unfortunately however, I was given the wrong roll cage. As I was away when it was delivered, I was none the wiser that the cage I was given was for the MX5 super cup, and MK3 cars! By some miracle my Grandad was able to fit it into my MK1 without compromising any struts (I told you he was good!). But when I arrived back to see it was the wrong roll cage welded into my car, there was an element of panic. Luckily, it actually exceeds the specifications for my class and is safer than the standard cages. This does however come at a cost due to there being two more struts on the cage, and thus more weight.

Over the next year I made adjustments and modifications to the car however possible. With help from my Grandad we removed the headlights to fit a new air intake through the front left light housing. We also built a new centre console from sheet aluminium, with a switch panel for with a kill switch, ignition button and other switches to be programmed in future. The steering wheel was replaced with a quick release D pattern steering wheel. This smaller design gives the driver more room in the cockpit and is much more comfortable to hold when racing. The quick release also makes getting in and out of the car much easier with the roll cage in place.

I also changed all the coolant hoses to a racing set, helping save weight and improve reliability. But one of the most intimidating jobs for me was attempting to reduce weight from behind the dashboard. Over the course of a few days early in to the first Covid Lockdown, I completed a full dash removal. I removed the heater Matrix and air con unit (surprisingly heavy!) and re-routed the coolant hoses to bypass entering the cockpit at all. I also removed all the vents and any un-needed materials from behind the dash. This cleared so much space, but my biggest task was tackling the next of wires that lay underneath

Being extremely careful not to strip any wires that would be needed for rear lights, dashboard etc. I ventured in clutching my wire cutters and holding my breath. By some miracle I managed to get most of the unwanted wires out of the car and the result was a much more streamlined and easier to read wiring loom behind the dash which I new would help immensely if something would go wrong on race day, much less wires to sort through and get confused with. Adding all the wire I took out resulted in a surprising amount of weight too, sadly I wasn’t able to put them on any scales but the job was well worth the hassle if only for the weight reduction.

The Final Stretch

The final additions I did myself was a while later as I needed to save up for the GAZ Gold Suspension kit, ROTA Slipstream wheels and Avon tyres that are mandatory for the series. These are one of the most drastic changes to the car setup and ones that I knew I would feel as soon as I would take it out on track. The GAZ Gold Suspension was rated at 500 on the front and 300 on the rear. This are really tough, track only shocks and also highly adjustable to help with setting up the car on track. The wheels are ROTA Slipstream wheels and are much more lightweight than my previous Daisy Mazda wheels. and also looked fantastic on the car. Fitting the suspensions was far from easy. My car had basic shocks in but these were obviously put in years ago, as the rubber had disintegrated and they had plenty of wear and tear. The rear shocks weren’t too bad other than a few sticky bolts here and there. However it was on the front that the real problems began to surface as the bolt holding the front front upper wishbone onto the car was a real pain to get off. Not only because of it sticking, but also because of it’s awkward location. But after a few cans of WD40, we managed to get them out and the new shocks were in. For the moment, I had the shocks set to their highest setting, as I did not ant to have the arches scraping or rough ground clearance when moving the car and transporting it. But seeing it sat back on the ground with the new suspension and wheels in place was fantastic and really made me feel after all these years everything was finally coming together.

The car was now ready to be sent of to Thrussington Garage for it’s final modifications to get it ready for racing!